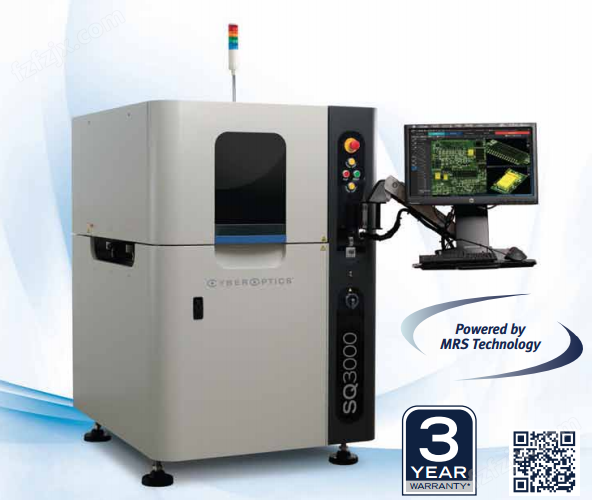

SQ3000AOI

产品简介

详细信息

INSPECTION CAPABILITIES

Inspection Speed : 40 cm2/sec (2D+3D)

Minimum Component Size : 0402 mm (01005 in.)

PCB Size: 510 x 510 mm (20 x 20 in.)

Component Height Clearance: 50mm

PCB Thickness: 0.3 – 5 mm

Component Types Inspected : Standard SMT (chips, J-lead, gull-wing, BGA, etc.), through- hole, odd-form,clips, connectors, header pins, and more

Component Defects: Missing, polarity, tombstone, billboard, flipped, wrong part, gross body andlead damage, and more

Solder Joint and Other Defects:Gold finger contamination, excess solder, insufficient solder, bridging,through-hole pins

3D Measurement Inspection : Lifted Lead, package coplanarity, polarity dimple and chamfer identification

Measurement Gage R&R : <10% @="" ±3σ="" (±80μm="" process="">

Z Height Accuracy : 1μm on certification target

Z Height Measurement Range: 6mm at spec, 24mm capability

VISION SYSTEM & TECHNOLOGY

Imagers : Multi-3D sensors

Resolution : Sub 10 μm

Image Processing : Autonomous Image Interpretation (AI2) Technology, Coplanarity and Lead Measurement

Programming Time: <15 minutes="" (for="" established="">

CAD Import : Any column-separated text file with ref designator, XY, Angle, Part no info;Valor process preparation

SYSTEM SPECIFICATIONS

Machine Interface: SMEMA, RS232 and Ethernet

Power Requirements: 100-120 VAC or 220-240 VAC, 50/60Hz, 10 amp max.

System Dimensions : 110 x 127 x 139 cm (W x D x H)

Weight : ≈965 kg (2127 lbs.)

OPTIONS

Barcode Reader, Rework station, SPC Software, Alignment Target