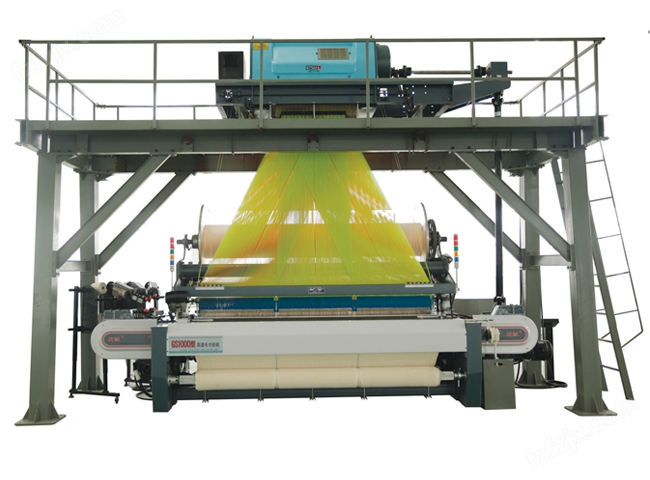

GS1100系列高速毛巾剑杆织机

产品简介

详细信息

友诚 GS1100 高速毛巾剑杆织机特点

产品特点:

友诚GS1100型高档毛巾剑杆织机采用电子送经、电子卷取、拥有发明的筘动式数控起毛圈机构,毛圈可由3~7纬任意转换,波浪毛、锯齿毛自动生成,并可在运行中自动变纬密,除能织造普通毛圈织物外,还可织造高低毛、凹凸毛、波浪毛、单面毛等高档毛圈织物。噪音低、震动小。

Features:

YOUCHENG GS1100 top grade terry rapier loom adopts electronic let-off and electronic take-up, digit control reed motion type looping system which has national patent, loop formation can be changed freely from 3~7 picks, wavy terry and serrated terry can be weaved automaticlly,and weft density can be changed automatically while the loom is running.

This model loom not only can weave common terry fabric, but also can weave up and down loop, high and low loop, wave-pile patterns, single cover loop and other top grade terry towel. Direct motor is an option for this model looms with the advantages of convenient maintenance and saving power. This type loom fills the blank of top grade terry loom in China, and reaches the international advanced level.

High speed, perfect performance. Dynamic loop formation controlled by sley movement can ensure weaving super quality terry towels, and form the superstandard of loop pattern.

技术规格

项目Item GS1100规格 GS1100 specification 筘幅 Reed width 筘幅:200、230、260、280、300、320、360cm Reed width:200、230、260、280、300、320、360cm 有效筘幅:公称筘幅减去0~80cm Width reduction: up to 80cm 织造范围 Yarn range 棉及合成纤维纱:500tex(1.2Ne)~5tex(120Ne) Cotton and Synthetic fibre yarn:500tex(1.2Ne)-5tex(120Ne) 长丝:10dte(9Td)~1650dte(1500Td) Filament yarns:10dte(9Td)~1650dte(1500Td) 织机速度 speed 设计转速:550转/分 Designed speed:550rpm 工艺转速:350~450转/分(依宽幅配置定) Practical speed:350~450rpm(depending on machine width and specification) 入纬率:1350米/分(依宽幅配置定) Filling insertion rates: up to 1350 m/min(depending on machine width and specification) 纬纱weft 纬纱选择:8色高速步进电机电子选纬器 Colour selection: high speed step-motor controlled electronic 8-colour-selector 储纬:定鼓存储式电子储纬器 Prewinders: FDP Electronic accumulator 纬剪:机械式剪刀 Weft cutter: mechanical cutter 动力power 传动控制:7.5kw三相异步伺服超级马达通过齿轮直接驱动,没有离合制动器 Driving control: rated three-phase 7.5kw motor drived by gear directly, no brake and clutch 开口shedding motion 高速电子多臂机,最多20片拉杆 High-speed electronic dobby with max 20 levers 电子提花机 Electronic jacquard 起圈 loop 伺服起圈:动态毛圈控制,由筘座运动形成毛圈。具有3-7纬自动控制起毛及转换功能,波浪毛、锯齿毛自动生成织造 Servo control:dynamic loop control, loop weaved by sley movement, automatic loop and switching from 3-7 picks,wavy terry and serrated terry can be weaved automaticlly 毛圈长度:0-24cmm之间任意设定,间隔精度可为0.1mm Loop height: 0-24mm( at will), the maximum difference accuracy can be up to 01.mm 打纬 beat-up 双侧共轭凸轮带动筘座 Conjugated cams in two sides with cam followers 引纬 Filling insertion 高速倒挂齿臂引纬机构,单排式导钩、开口要求更小更清晰 High speed upside down pinion rack mechanism with single row guide hook, smaller and more clear shedding 送经 Let-off 连续式交流伺服电子送经 Continuous ,electronically controlled let-off system 地径边盘直径:ϕ800mm,毛经边盘直径:ϕ1000mm Warp beam diameter: ground 800mm, pile 1000mm 卷取take -up 连续式交流伺服电子卷取 Continuous ,electronically controlled take-up system 机内卷布直径ϕ600mm,机外卷布ϕ1200mm(配大卷装) Diameter of cloth roll:standard 600mm(on loom) 1200mm(outside loom) 纬密范围:5~150根/厘米 Pick density range: 5-150 picks/cm 布边 selvedge formation 绞边装置:高速电子绞边或普通电子绞边 Selvedge device: normal or high-speed electronic controlled 边剪:机械式,可选电子式 Selvedge cutter: mechanical or electronic(optional) 边撑:左右独立边撑 Temple: LH&RH individual temple 润滑 lubrication 集中压力供油喷淋润滑、油浴润滑、配油压报警 Pressurised oil circulation system with continuous filtration, bath oil with oil pressure alarm 停车装置 Stop motions 经停:纬纱2列、毛纱4列,电气触点式停经装置 Warp yarn: two rows for weft yarn, four rows for terry warp, electric contact type stop motion 纬停:电子式高灵敏压电检测装置 Weft yarn: high-sensitivity piezo-electric detector 其它:绞边纱、废边纱断头自停 Others: stop motion for leno and false selvage yarn 停车显示:控制面板显示停车原因,多功能5色灯停车显示 Stop display: the panel shows the stop reason, 5-colour multi-function indication lamps 自动功能 automatic 自动定位停车/慢速寻纬/织口补偿、调整经纱张力,自动检测/复位/故障显示 Automatic:pointing stop/ slow motion, pick finding/cloth-fell compensation/adjusting warp tension/self-diagnosis function/reset/fault indication 电气控制 Electric control 控制:多功能CPU控制系统,能控制、监控、自动诊断、信息显示 Controlling: functional CUP control system, can control, scout, auto diagnose, information showing 显示:大液晶屏显示双向通讯,按钮操作,即时调整/设定参数、编程- Display: big LCD shoeing bidirectional communication, button operation,, instant adjustment/parameter setting, programme making