TRBL-H高速圆瓶贴标机

Vertical round bottle labeling machine

| 型号 Model | TRBL-H |

| 产量(件/分钟) Production (pieces / min) | 200-800件/分钟(与物料及标签尺寸有关) 200-800 pieces / minute (related to material and label size) |

| 操作方向 Operation direction | 左进右出或右进左出 Left to right or right to left |

| 贴标精度 Labeling accuracy | ±0.5 ㎜ |

| 标签类型 Label type | 不干胶标签,透明或不透明 Sticker, transparent or opaque |

| 卷标内径 Volume inside diameter | 76 ㎜ |

| 卷标外径 Volume outer diameter | 420 ㎜(max) |

| 标签尺寸 Label size | 长度10-300㎜,高度10-80㎜ Length 10-300㎜, height 10-80㎜ |

| 贴标物体尺寸 Labeling object size | 直径40-120㎜ 20-100㎜ in diameter |

| 工作气压 working pressure | 0.6Mpa |

| 电源及功率 Power and power | 220VAC±10% 50Hz,0.8Kw |

| 适用环境 Applicable environment | 温度5-40℃,湿度15-85%(无冷凝) Temperature 5-40 ° C, humidity 15-85% (no condensation) |

| 重量 (kg) | 450kg |

| 机器尺寸 Machine size | 2800(L)* 1800 (W) *1900 (H) ㎜ |

| 备注 Remarks | 可接受非标定制 Acceptable non-standard customization |

自动高速圆瓶贴标机

基本用途

◆ TRBL-H不干胶贴标机属于自动高速圆瓶贴标机系列,适用在圆柱形物体贴标签或不干胶膜,如圆形塑料瓶、圆形玻璃瓶、PET瓶等,更换覆标机构可适用于圆周体贴标,贴标机械设备应用于产品的全周围和半周围贴标。

可选配在线打印贴标机或喷码机到贴标头,可实现在标签上打印电子监管码、生产日期、批号和喷印条码、二维码追溯等信息。

可选视觉检测设备、输送带/传送带,实现对产品进行视觉检测剔除功能,可增加自动化生产线、流水线及码垛机器人对后段包装产品的装箱、封箱等。

产品特点

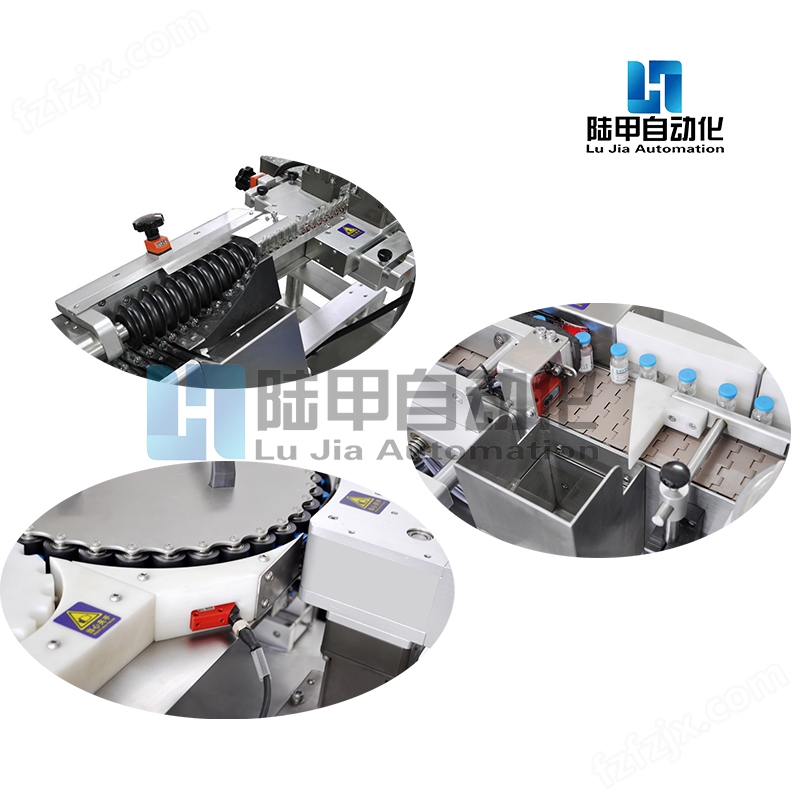

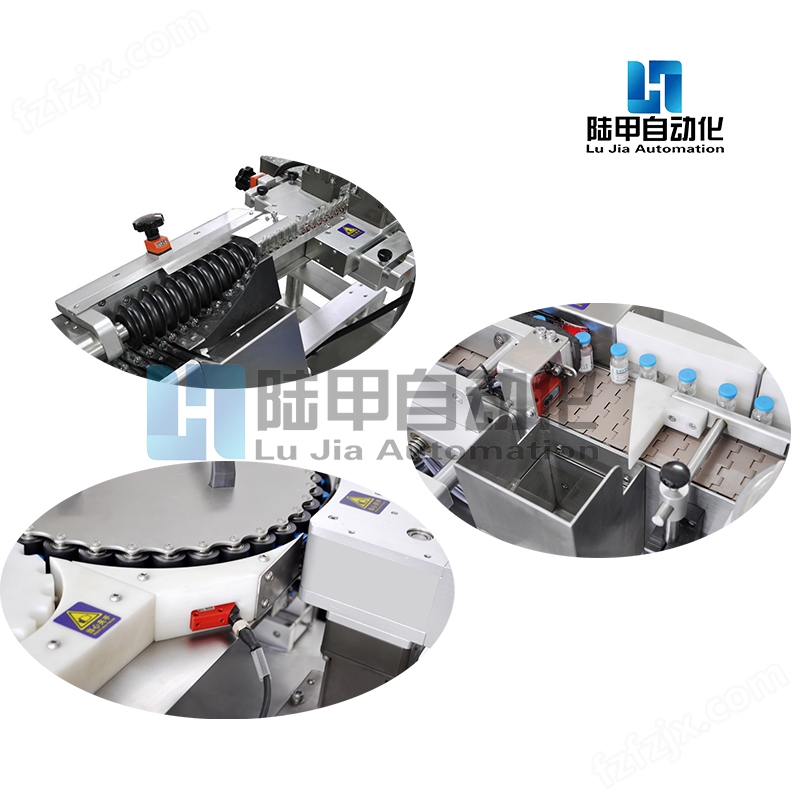

◆ 贴标精度高,贴标方式采用回转式星盘结构,立进、立贴、立出的运行贴标模式,大幅减少碎瓶故障率、解决收料问题,保证标签牵引过程中不左右偏移;偏心轮技术应用于牵引机构,牵引标签不打滑,确保出标精确;

◆ 坚固耐用,采用三杆调整机构,充分利用三角形的稳定性,整机坚实耐用;

◆ 稳定性高,松下(Panasonic)+PLC/西门子(Siemens)+松下触摸屏+松下针形电眼+德国劳易测标签电眼组成的电控系统,支持设备7×24小时运转;

◆ 调整简单,人性化设计自由度可调,不同产品之间的转换变得简单、省时;

◆ 应用灵活,可单机生产或接流水线生产,生产现场布局简单;

◆ 智能控制,自动光电追踪,具备无物不贴标,无标自动校正和标签自动检测功能,防止漏贴和标签浪费;

◆ 触摸屏操作界面,全中文注释和完善的故障提示功能,各种参数调整简单快捷,操作方便;

◆ 功能强大,具有生产计数功能,省电功能,生产数设定提示功能,参数设置保护功能,方便生产管理;

◆ 可选配功能和部件:

①热打码/喷码功能;

②自动收料功能(结合产品考虑);

③自动上料功能(结合产品考虑);

④增加贴标装置;

⑤其他功能(按客户要求订做)

适用范围

◆ 适用标签:不干胶标签,不干胶膜,电子监管码,条形码等。

◆ 适用产品:要求在底面、大弧度面上贴附标签或膜的产品。

◆ 应用行业:贴标机应用与医药、日化、食品等行业的圆柱型包装容器的自动贴标(如:医药行业的西林瓶贴标,日化/食品行业的圆瓶贴标、方瓶贴标,与现场配套的生产线贴标)

◆ 应用实例:PET瓶、牛奶瓶、圆瓶、饮料瓶等。

工作原理

◆ 核心工作原理:传感器检测到产品经过,传回信号到贴标控制系统,信号经过PLC处理后,在适当时刻送出标签贴附在产品设定位置上,产品流经覆标装置,标签被覆牢固,一张标签的贴附动作完成。

◆ 操作过程:放产品(可接流水线)—>产品输送(自动实现)—>产品纠正(自动实现)—>产品检测(自动实现)—>贴标(自动实现)—>覆标(自动实现)—>收集已贴标产品。

Automatic High Speed Bottle Labeling Machine

Basic uses

TRBL-H self-adhesive labeling machine belongs to the automatic high-speed cylinder labeling machine series. It is suitable for labeling cylindrical objects or dry film, such as circular plastic bottles, circular glass bottles, PET bottles, etc. Replacing labeling mechanism can be applied to labeling circular bodies, and labeling machinery and equipment can be applied to labeling all around and half around products.

Optional on-line printing labeling machine or jet printer to label head can print electronic supervision code, production date, batch number and jet printing bar code, two-dimensional code traceability and other information on the label.

Optional visual inspection equipment, conveyor belt/conveyor belt can be used to realize visual inspection and removal of products. Automated production lines, assembly lines and stacking robots can be added to pack and seal the back packing products.

Product characteristics

High labeling accuracy, the labeling mode adopts rotary star disc structure, vertical, standing operation labeling mode, greatly reduces the breakdown rate of bottles, solves the problem of collecting materials, and ensures that the label does not deviate left and right in the process of traction; eccentric wheel technology is applied to traction mechanism, and the traction label does not slip to ensure the accuracy of the labeling;

Strong and durable, using three-bar adjusting mechanism, making full use of the stability of the triangle, the machine is solid and durable;

High stability, Panasonic + PLC / Siemens + Panasonic touch screen + Panasonic needle electro-eye + German label electro-eye electronic control system, support equipment 7 x 24 hours operation;

Simple adjustment, adjustable freedom of humanized design, simple and time-saving conversion between different products;

Flexible application, single machine production or assembly line production, simple production site layout;

Intelligent control, automatic photoelectric tracking, with no label, no label automatic correction and automatic label detection function, to prevent leakage and label waste;

Touch screen operation interface, full Chinese annotation and perfect fault prompt function, various parameters adjustment is simple and fast, easy to operate;

Powerful function, with production counting function, power saving function, production number setting prompt function, parameter setting protection function, convenient production management;

Optional functions and components:

(1) Hot code/jet code function;

(2) Automatic collection function (considering product);

(3) Automatic feeding function (considering product);

(4) Adding labeling device;

(5) Other functions (customized according to customer requirements)

Scope of application

Applicable Labels: Self-adhesive Labels, Self-adhesive Films, Electronic Supervision Codes, Bar Codes, etc.

Applicable products: products requiring labels or membranes to be attached on the bottom and large radian surfaces.

Application Industry: Labeling Machine Application and Automatic Labeling of Cylindrical Packaging Containers in Pharmaceutical, Daily Chemical and Food Industries (e.g. Silin Bottle Labeling in Pharmaceutical Industries, Round Bottle Labeling in Daily Chemical/Food Industries, Square Bottle Labeling, and Production Line Labeling Matched with the Field)

Application examples: PET bottle, milk bottle, round bottle, beverage bottle, etc.

Working principle

_Core working principle: Sensor detects product process, sends back signal to labeling control system. After signal is processed by PLC, label is sent out and attached to the set position of the product at the appropriate time. The product flows through the labeling device, the label is firmly covered, and the affixing action of a label is completed.

_Operation process: release product (connectable pipeline) - > product delivery (automatic realization) > Product correction (automatic realization) > product detection (automatic realization) > labeling (automatic realization) > labeling (automatic realization) > collection of labeled products.