品牌

其他厂商性质

烟台市所在地

优势特点:

1、减少了磨擦,降低能耗,磨机启动容易。2、保留普通磨机的端盖结构形式,大口径进出料口,处理量大。3、整体机架,安装精度高,土建、安装简便,周期短。4、取消联合给料器采用鼓形给料器,没有惯性冲击,设备运行平稳,减少磨机停机维修时间,提高了磨机使用效率。

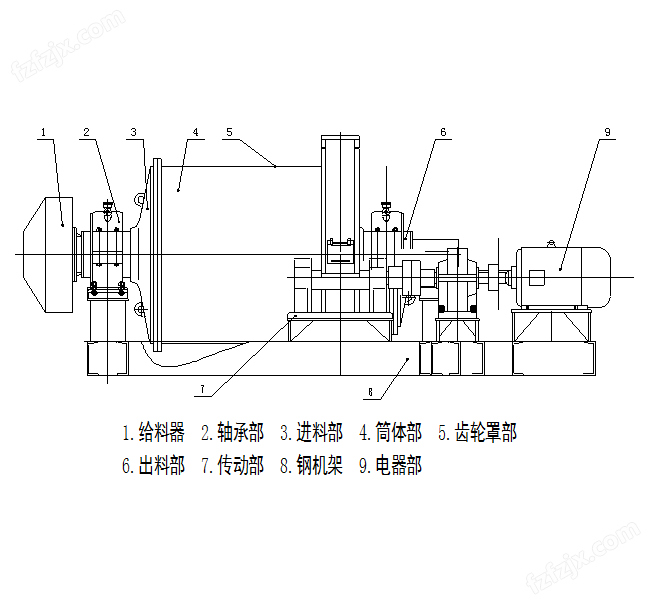

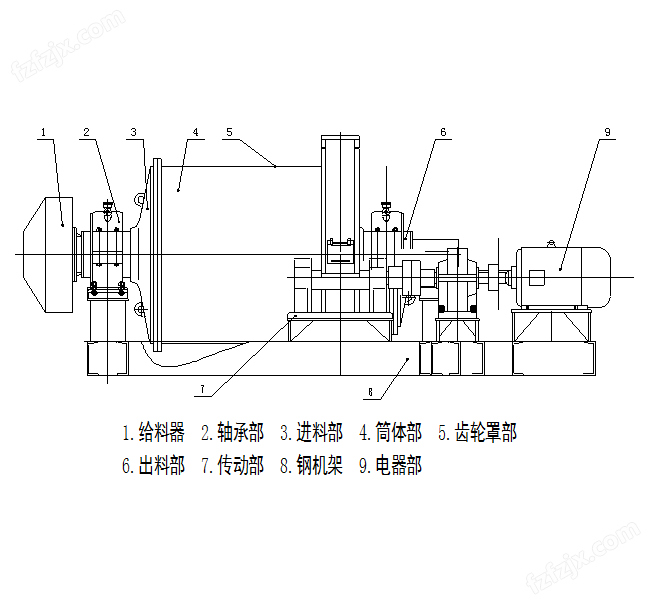

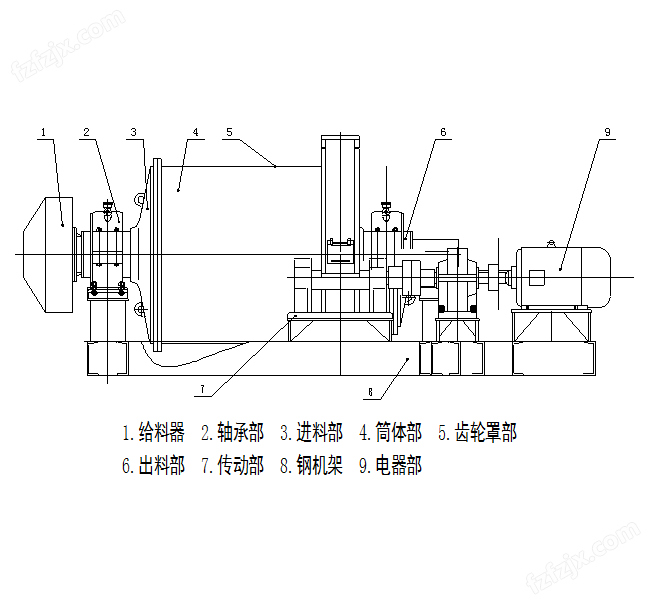

工作原理:

本机为卧式筒形旋转装置,外沿齿轮传动,两仓,格子型球磨机。物料由进料装置经入料中空轴螺旋均匀地进入磨机仓,该仓内有阶梯衬板或波纹衬板,内装不同规格钢球,筒体转动产生离心力将钢球带到一定高度后落下,对物料产生重击和研磨作用。物料在仓达到粗磨后,经单层隔仓板进入第二仓,该仓内镶有平衬板,内有钢球,将物料进一步研磨。粉状物通过卸料箅板排出,完成粉磨作业。

技术参数:

| GM系列滚动轴承球磨机技术参数表 | ||||||||||

| 型号 | 规格 | 筒体转速(r/min) | 装球重量(t) | 出料粒度(mm) | 给料粒度(mm) | 产量 | 配套电动机 cooperate motor | 外形尺寸(mm) | 重量(kg) | |

| Model | standard | Revolution of the | weight | exit size | size of supplying minerals | output | 型号 model | 功率 (kw) power | dimension (L×W×H) | weight |

| GZM0912 | φ900×1200 | 41.6 | 1.1 | 0.074-0.3 | 25 | 0.3-0.9 | Y180L-8 | 11 | 3843×1850×1400 | 4210 |

| GZM0921 | φ900×2100 | 41.6 | 1.8 | 0.074-0.3 | 25 | 0.6-1.5 | Y180L-6 | 15 | 4743×1850×1400 | 6660 |

| GZM0933 | φ900×3300 | 41.6 | 2.8 | 0.074-0.3 | 25 | 0.9-2.3 | Y225M-6 | 30 | 5943×1850×1400 | 7770 |

| GZM1224 | φ1200×2400 | 35.1 | 4 | 0.074-0.3 | 25 | 1.6-4.1 | Y280S-8 | 37 | 5540×2300×1850 | 10020 |

| GZM1228 | φ1200×2800 | 35.1 | 4.6 | 0.074-0.3 | 25 | 1.9-4.8 | Y280M-8 | 45 | 5940×2300×1850 | 10935 |

| GZM1232 | φ1200×3200 | 35.1 | 5.3 | 0.074-0.3 | 25 | 2.2-5.5 | Y280M-8 | 45 | 6340×2300×1850 | 11230 |

| GZM1244 | φ1200×4400 | 35.1 | 7.3 | 0.074-0.3 | 25 | 3.0-7.5 | Y135S-8 | 55 | 6340×2300×1850 | 13210 |

| GZM1324 | φ1300×2400 | 30.2 | 4.5 | 0.074-0.3 | 25 | 1.5-3.5 | Y280S-8 | 37 | 7540×2300×1850 | 10210 |

| GZM1328 | φ1300×2800 | 30.2 | 5.2 | 0.074-0.3 | 25 | 2.0-4.5 | Y280M-8 | 45 | 5035×2370×1880 | 11290 |

| GZM1334 | φ1300×3400 | 30.2 | 6.5 | 0.074-0.3 | 25 | 2.2-5.0 | Y280M-8 | 75 | 5435×2370×1880 | 13117 |

| GZM1524 | φ1500×2400 | 30.2 | 7 | 0.074-0.3 | 25 | 2.8-6.5 | YR280S-8 | 55 | 6035×2370×1880 | 15340 |

| GZM1530 | φ1300×3000 | 30.7 | 9 | 0.074-0.3 | 25 | 3.5-8 | Y280M-8 | 80 | 6830×2930×2060 | 16843 |

| GZM1533 | φ1500×3300 | 30.7 | 10 | 0.074-0.3 | 25 | 4.0-9 | YR280M-8 | 95 | 7430×2930×2060 | 17849 |

| GZM1536 | φ1500×3600 | 30.7 | 11 | 0.074-0.3 | 25 | 4.5-10 | Y280M-8 | 95 | 7730×2930×2060 | 18649 |

| GZM1542 | φ1500×4200 | 30.7 | 12.5 | 0.074-0.3 | 25 | 5.0-11 | Y315S-8 | 110 | 8030×2930×2060 | 19330 |

| GZM1545 | φ1500×4500 | 30.7 | 13.5 | 0.074-0.3 | 25 | 5.5-13.5 | YR280S-8 | 110 | 8630×2930×2060 | 20000 |

| GZM1557 | φ1500×5700 | 30.7 | 17 | 0.074-0.3 | 25 | 7.0-15.5 | YR280M-8 | 130 | 8930×2930×2060 | 23597 |

| GZM1563 | φ1500×6300 | 30.7 | 19 | 0.074-0.3 | 25 | 8.0-17 | JR117-8 | 155 | 10130×2930×2060 | 24390 |

| GZM1830 | φ1500×3000 | 25.04 | 13 | 0.074-0.3 | 25 | 3.0-17 | JR125-8 | 130 | 10730×2930×2060 | 29490 |

| GZM1834 | φ1500×3400 | 25.04 | 14 | 0.074-0.3 | 25 | 3.3-20 | JR126-8 | 155 | 9525×3960×2250 | 30390 |

| GZM1836 | φ1500×3600 | 25.04 | 15 | 0.074-0.3 | 25 | 4.0-21.5 | JR126-8 | 155 | 9925×3960×2250 | 31600 |

| GZM1840 | φ1500×4000 | 25.04 | 17 | 0.074-0.3 | 25 | 4.5-24 | JR127-8 | 155 | 10125×3960×2250 | 32700 |

| GZM1842 | φ1830×4200 | 25.04 | 18 | 0.074-0.3 | 25 | 5.0-25 | JR128-8 | 180 | 10525×3960×2250 | 33490 |

| GZM1844 | φ1830×4400 | 25.04 | 19 | 0.074-0.3 | 25 | 5.2-26 | JR128-8 | 180 | 10725×3960×2250 | 34210 |

| GZM1852 | φ1830×5200 | 25.04 | 21 | 0.074-0.3 | 25 | 6.5-32.5 | JR128-8 | 180 | 11725×3960×2250 | 37715 |

| GZM1864 | φ1830×6400 | 25.04 | 27 | 0.074-0.3 | 25 | 8.0-40 | JR136-8 | 210 | 12925×3960×2250 | 42440 |

| GZM2122 | φ1830×2200 | 23.8 | 15 | 0.074-0.5 | 25 | 3.0-22 | JR136-8 | 130 | 7775×4060×3400 | 38793 |

| GZM2130 | φ1830×3000 | 23.8 | 20 | 0.074-0.5 | 25 | 4.0-30 | JR137-8 | 180 | 8475×4060×3400 | 41965 |

| GZM2136 | φ2100×3750 | 23.8 | 21 | 0.074-0.5 | 25 | 5.0-37 | JR128-8 | 210 | 9225×4060×3400 | 44551 |

| GZM2140 | φ2100×4000 | 23.8 | 22 | 0.074-0.5 | 25 | 5.2-39 | JR128-8 | 245 | 9475×4060×3400 | 46697 |

| GZM2430 | φ2400×3000 | 22 | 20 | 0.074-0.5 | 25 | 8-50 | JR136-8 | 320 | 8420×4064×3594 | 54900 |

| GZM2460 | φ2400×6000 | 22 | 35 | 0.074-0.5 | 25 | 8-70 | JR137-8 | 380 | 11520×4064×3594 | 75800 |

| GZM2733 | φ2700×3300 | 21.7 | 32 | 0.074-0.5 | 25 | 12-92 | JR137-8 | 320 | 9010×5410×3150 | 73315 |

| GZM2736 | φ2700×3600 | 21.7 | 34 | 0.074-0.5 | 25 | 12.5-98 | JR138-8 | 380 | 9314×5410×3150 | 75410 |

| GZM2742 | φ2700×4200 | 21.7 | 38 | 0.074-0.5 | 25 | 15-118 | JR157-8 | 380 | 10035×5410×3150 | 80647 |

工作原理:

本机为卧式筒形旋转装置,外沿齿轮传动,两仓,格子型球磨机。物料由进料装置经入料中空轴螺旋均匀地进入磨机仓,该仓内有阶梯衬板或波纹衬板,内装不同规格钢球,筒体转动产生离心力将钢球带到一定高度后落下,对物料产生重击和研磨作用。物料在仓达到粗磨后,经单层隔仓板进入第二仓,该仓内镶有平衬板,内有钢球,将物料进一步研磨。粉状物通过卸料箅板排出,完成粉磨作业。

优势特点:

1、减少了磨擦,降低能耗,磨机启动容易。2、保留普通磨机的端盖结构形式,大口径进出料口,处理量大。3、整体机架,安装精度高,土建、安装简便,周期短。4、取消联合给料器采用鼓形给料器,没有惯性冲击,设备运行平稳,减少磨机停机维修时间,提高了磨机使用效率。

技术参数:

| GM系列滚动轴承球磨机技术参数表 | ||||||||||

| 型号 | 规格 | 筒体转速(r/min) | 装球重量(t) | 出料粒度(mm) | 给料粒度(mm) | 产量 | 配套电动机 cooperate motor | 外形尺寸(mm) | 重量(kg) | |

| Model | standard | Revolution of the | weight | exit size | size of supplying minerals | output | 型号 model | 功率 (kw) power | dimension (L×W×H) | weight |

| GZM0912 | φ900×1200 | 41.6 | 1.1 | 0.074-0.3 | 25 | 0.3-0.9 | Y180L-8 | 11 | 3843×1850×1400 | 4210 |

| GZM0921 | φ900×2100 | 41.6 | 1.8 | 0.074-0.3 | 25 | 0.6-1.5 | Y180L-6 | 15 | 4743×1850×1400 | 6660 |

| GZM0933 | φ900×3300 | 41.6 | 2.8 | 0.074-0.3 | 25 | 0.9-2.3 | Y225M-6 | 30 | 5943×1850×1400 | 7770 |

| GZM1224 | φ1200×2400 | 35.1 | 4 | 0.074-0.3 | 25 | 1.6-4.1 | Y280S-8 | 37 | 5540×2300×1850 | 10020 |

| GZM1228 | φ1200×2800 | 35.1 | 4.6 | 0.074-0.3 | 25 | 1.9-4.8 | Y280M-8 | 45 | 5940×2300×1850 | 10935 |

| GZM1232 | φ1200×3200 | 35.1 | 5.3 | 0.074-0.3 | 25 | 2.2-5.5 | Y280M-8 | 45 | 6340×2300×1850 | 11230 |

| GZM1244 | φ1200×4400 | 35.1 | 7.3 | 0.074-0.3 | 25 | 3.0-7.5 | Y135S-8 | 55 | 6340×2300×1850 | 13210 |

| GZM1324 | φ1300×2400 | 30.2 | 4.5 | 0.074-0.3 | 25 | 1.5-3.5 | Y280S-8 | 37 | 7540×2300×1850 | 10210 |

| GZM1328 | φ1300×2800 | 30.2 | 5.2 | 0.074-0.3 | 25 | 2.0-4.5 | Y280M-8 | 45 | 5035×2370×1880 | 11290 |

| GZM1334 | φ1300×3400 | 30.2 | 6.5 | 0.074-0.3 | 25 | 2.2-5.0 | Y280M-8 | 75 | 5435×2370×1880 | 13117 |

| GZM1524 | φ1500×2400 | 30.2 | 7 | 0.074-0.3 | 25 | 2.8-6.5 | YR280S-8 | 55 | 6035×2370×1880 | 15340 |

| GZM1530 | φ1300×3000 | 30.7 | 9 | 0.074-0.3 | 25 | 3.5-8 | Y280M-8 | 80 | 6830×2930×2060 | 16843 |

| GZM1533 | φ1500×3300 | 30.7 | 10 | 0.074-0.3 | 25 | 4.0-9 | YR280M-8 | 95 | 7430×2930×2060 | 17849 |

| GZM1536 | φ1500×3600 | 30.7 | 11 | 0.074-0.3 | 25 | 4.5-10 | Y280M-8 | 95 | 7730×2930×2060 | 18649 |

| GZM1542 | φ1500×4200 | 30.7 | 12.5 | 0.074-0.3 | 25 | 5.0-11 | Y315S-8 | 110 | 8030×2930×2060 | 19330 |

| GZM1545 | φ1500×4500 | 30.7 | 13.5 | 0.074-0.3 | 25 | 5.5-13.5 | YR280S-8 | 110 | 8630×2930×2060 | 20000 |

| GZM1557 | φ1500×5700 | 30.7 | 17 | 0.074-0.3 | 25 | 7.0-15.5 | YR280M-8 | 130 | 8930×2930×2060 | 23597 |

| GZM1563 | φ1500×6300 | 30.7 | 19 | 0.074-0.3 | 25 | 8.0-17 | JR117-8 | 155 | 10130×2930×2060 | 24390 |

| GZM1830 | φ1500×3000 | 25.04 | 13 | 0.074-0.3 | 25 | 3.0-17 | JR125-8 | 130 | 10730×2930×2060 | 29490 |

| GZM1834 | φ1500×3400 | 25.04 | 14 | 0.074-0.3 | 25 | 3.3-20 | JR126-8 | 155 | 9525×3960×2250 | 30390 |

| GZM1836 | φ1500×3600 | 25.04 | 15 | 0.074-0.3 | 25 | 4.0-21.5 | JR126-8 | 155 | 9925×3960×2250 | 31600 |

| GZM1840 | φ1500×4000 | 25.04 | 17 | 0.074-0.3 | 25 | 4.5-24 | JR127-8 | 155 | 10125×3960×2250 | 32700 |

| GZM1842 | φ1830×4200 | 25.04 | 18 | 0.074-0.3 | 25 | 5.0-25 | JR128-8 | 180 | 10525×3960×2250 | 33490 |

| GZM1844 | φ1830×4400 | 25.04 | 19 | 0.074-0.3 | 25 | 5.2-26 | JR128-8 | 180 | 10725×3960×2250 | 34210 |

| GZM1852 | φ1830×5200 | 25.04 | 21 | 0.074-0.3 | 25 | 6.5-32.5 | JR128-8 | 180 | 11725×3960×2250 | 37715 |

| GZM1864 | φ1830×6400 | 25.04 | 27 | 0.074-0.3 | 25 | 8.0-40 | JR136-8 | 210 | 12925×3960×2250 | 42440 |

| GZM2122 | φ1830×2200 | 23.8 | 15 | 0.074-0.5 | 25 | 3.0-22 | JR136-8 | 130 | 7775×4060×3400 | 38793 |

| GZM2130 | φ1830×3000 | 23.8 | 20 | 0.074-0.5 | 25 | 4.0-30 | JR137-8 | 180 | 8475×4060×3400 | 41965 |

| GZM2136 | φ2100×3750 | 23.8 | 21 | 0.074-0.5 | 25 | 5.0-37 | JR128-8 | 210 | 9225×4060×3400 | 44551 |

| GZM2140 | φ2100×4000 | 23.8 | 22 | 0.074-0.5 | 25 | 5.2-39 | JR128-8 | 245 | 9475×4060×3400 | 46697 |

| GZM2430 | φ2400×3000 | 22 | 20 | 0.074-0.5 | 25 | 8-50 | JR136-8 | 320 | 8420×4064×3594 | 54900 |

| GZM2460 | φ2400×6000 | 22 | 35 | 0.074-0.5 | 25 | 8-70 | JR137-8 | 380 | 11520×4064×3594 | 75800 |

| GZM2733 | φ2700×3300 | 21.7 | 32 | 0.074-0.5 | 25 | 12-92 | JR137-8 | 320 | 9010×5410×3150 | 73315 |

| GZM2736 | φ2700×3600 | 21.7 | 34 | 0.074-0.5 | 25 | 12.5-98 | JR138-8 | 380 | 9314×5410×3150 | 75410 |

| GZM2742 | φ2700×4200 | 21.7 | 38 | 0.074-0.5 | 25 | 15-118 | JR157-8 | 380 | 10035×5410×3150 | 80647 |

技术参数:

| GM系列滚动轴承球磨机技术参数表 | ||||||||||

| 型号 | 规格 | 筒体转速(r/min) | 装球重量(t) | 出料粒度(mm) | 给料粒度(mm) | 产量 | 配套电动机 cooperate motor | 外形尺寸(mm) | 重量(kg) | |

| Model | standard | Revolution of the | weight | exit size | size of supplying minerals | output | 型号 model | 功率 (kw) power | dimension (L×W×H) | weight |

| GZM0912 | φ900×1200 | 41.6 | 1.1 | 0.074-0.3 | 25 | 0.3-0.9 | Y180L-8 | 11 | 3843×1850×1400 | 4210 |

| GZM0921 | φ900×2100 | 41.6 | 1.8 | 0.074-0.3 | 25 | 0.6-1.5 | Y180L-6 | 15 | 4743×1850×1400 | 6660 |

| GZM0933 | φ900×3300 | 41.6 | 2.8 | 0.074-0.3 | 25 | 0.9-2.3 | Y225M-6 | 30 | 5943×1850×1400 | 7770 |

| GZM1224 | φ1200×2400 | 35.1 | 4 | 0.074-0.3 | 25 | 1.6-4.1 | Y280S-8 | 37 | 5540×2300×1850 | 10020 |

| GZM1228 | φ1200×2800 | 35.1 | 4.6 | 0.074-0.3 | 25 | 1.9-4.8 | Y280M-8 | 45 | 5940×2300×1850 | 10935 |

| GZM1232 | φ1200×3200 | 35.1 | 5.3 | 0.074-0.3 | 25 | 2.2-5.5 | Y280M-8 | 45 | 6340×2300×1850 | 11230 |

| GZM1244 | φ1200×4400 | 35.1 | 7.3 | 0.074-0.3 | 25 | 3.0-7.5 | Y135S-8 | 55 | 6340×2300×1850 | 13210 |

| GZM1324 | φ1300×2400 | 30.2 | 4.5 | 0.074-0.3 | 25 | 1.5-3.5 | Y280S-8 | 37 | 7540×2300×1850 | 10210 |

| GZM1328 | φ1300×2800 | 30.2 | 5.2 | 0.074-0.3 | 25 | 2.0-4.5 | Y280M-8 | 45 | 5035×2370×1880 | 11290 |

| GZM1334 | φ1300×3400 | 30.2 | 6.5 | 0.074-0.3 | 25 | 2.2-5.0 | Y280M-8 | 75 | 5435×2370×1880 | 13117 |

| GZM1524 | φ1500×2400 | 30.2 | 7 | 0.074-0.3 | 25 | 2.8-6.5 | YR280S-8 | 55 | 6035×2370×1880 | 15340 |

| GZM1530 | φ1300×3000 | 30.7 | 9 | 0.074-0.3 | 25 | 3.5-8 | Y280M-8 | 80 | 6830×2930×2060 | 16843 |

| GZM1533 | φ1500×3300 | 30.7 | 10 | 0.074-0.3 | 25 | 4.0-9 | YR280M-8 | 95 | 7430×2930×2060 | 17849 |

| GZM1536 | φ1500×3600 | 30.7 | 11 | 0.074-0.3 | 25 | 4.5-10 | Y280M-8 | 95 | 7730×2930×2060 | 18649 |

| GZM1542 | φ1500×4200 | 30.7 | 12.5 | 0.074-0.3 | 25 | 5.0-11 | Y315S-8 | 110 | 8030×2930×2060 | 19330 |

| GZM1545 | φ1500×4500 | 30.7 | 13.5 | 0.074-0.3 | 25 | 5.5-13.5 | YR280S-8 | 110 | 8630×2930×2060 | 20000 |

| GZM1557 | φ1500×5700 | 30.7 | 17 | 0.074-0.3 | 25 | 7.0-15.5 | YR280M-8 | 130 | 8930×2930×2060 | 23597 |

| GZM1563 | φ1500×6300 | 30.7 | 19 | 0.074-0.3 | 25 | 8.0-17 | JR117-8 | 155 | 10130×2930×2060 | 24390 |

| GZM1830 | φ1500×3000 | 25.04 | 13 | 0.074-0.3 | 25 | 3.0-17 | JR125-8 | 130 | 10730×2930×2060 | 29490 |

| GZM1834 | φ1500×3400 | 25.04 | 14 | 0.074-0.3 | 25 | 3.3-20 | JR126-8 | 155 | 9525×3960×2250 | 30390 |

| GZM1836 | φ1500×3600 | 25.04 | 15 | 0.074-0.3 | 25 | 4.0-21.5 | JR126-8 | 155 | 9925×3960×2250 | 31600 |

| GZM1840 | φ1500×4000 | 25.04 | 17 | 0.074-0.3 | 25 | 4.5-24 | JR127-8 | 155 | 10125×3960×2250 | 32700 |

| GZM1842 | φ1830×4200 | 25.04 | 18 | 0.074-0.3 | 25 | 5.0-25 | JR128-8 | 180 | 10525×3960×2250 | 33490 |

| GZM1844 | φ1830×4400 | 25.04 | 19 | 0.074-0.3 | 25 | 5.2-26 | JR128-8 | 180 | 10725×3960×2250 | 34210 |

| GZM1852 | φ1830×5200 | 25.04 | 21 | 0.074-0.3 | 25 | 6.5-32.5 | JR128-8 | 180 | 11725×3960×2250 | 37715 |

| GZM1864 | φ1830×6400 | 25.04 | 27 | 0.074-0.3 | 25 | 8.0-40 | JR136-8 | 210 | 12925×3960×2250 | 42440 |

| GZM2122 | φ1830×2200 | 23.8 | 15 | 0.074-0.5 | 25 | 3.0-22 | JR136-8 | 130 | 7775×4060×3400 | 38793 |

| GZM2130 | φ1830×3000 | 23.8 | 20 | 0.074-0.5 | 25 | 4.0-30 | JR137-8 | 180 | 8475×4060×3400 | 41965 |

| GZM2136 | φ2100×3750 | 23.8 | 21 | 0.074-0.5 | 25 | 5.0-37 | JR128-8 | 210 | 9225×4060×3400 | 44551 |

| GZM2140 | φ2100×4000 | 23.8 | 22 | 0.074-0.5 | 25 | 5.2-39 | JR128-8 | 245 | 9475×4060×3400 | 46697 |

| GZM2430 | φ2400×3000 | 22 | 20 | 0.074-0.5 | 25 | 8-50 | JR136-8 | 320 | 8420×4064×3594 | 54900 |

| GZM2460 | φ2400×6000 | 22 | 35 | 0.074-0.5 | 25 | 8-70 | JR137-8 | 380 | 11520×4064×3594 | 75800 |

| GZM2733 | φ2700×3300 | 21.7 | 32 | 0.074-0.5 | 25 | 12-92 | JR137-8 | 320 | 9010×5410×3150 | 73315 |

| GZM2736 | φ2700×3600 | 21.7 | 34 | 0.074-0.5 | 25 | 12.5-98 | JR138-8 | 380 | 9314×5410×3150 | 75410 |

| GZM2742 | φ2700×4200 | 21.7 | 38 | 0.074-0.5 | 25 | 15-118 | JR157-8 | 380 | 10035×5410×3150 | 80647 |

优势特点:

1、减少了磨擦,降低能耗,磨机启动容易。2、保留普通磨机的端盖结构形式,大口径进出料口,处理量大。3、整体机架,安装精度高,土建、安装简便,周期短。4、取消联合给料器采用鼓形给料器,没有惯性冲击,设备运行平稳,减少磨机停机维修时间,提高了磨机使用效率。

工作原理:

本机为卧式筒形旋转装置,外沿齿轮传动,两仓,格子型球磨机。物料由进料装置经入料中空轴螺旋均匀地进入磨机仓,该仓内有阶梯衬板或波纹衬板,内装不同规格钢球,筒体转动产生离心力将钢球带到一定高度后落下,对物料产生重击和研磨作用。物料在仓达到粗磨后,经单层隔仓板进入第二仓,该仓内镶有平衬板,内有钢球,将物料进一步研磨。粉状物通过卸料箅板排出,完成粉磨作业。